In current times, 3D printing has become the most resourceful tool for the designers and the engineers. With the help of this technology, they are able to do “rapid prototyping” as it helps them in creating a physical copy of the design.

But the only drawback that the designers had to experience was that for every revised design, the printing was done separately. This way, designers had to undergo multiple attempts of printing, until they had the final design in their hand.

Therefore, a new interactive 3D printing system has been developed by the scientists in Washington that will let you make changes in the model, even when it is in the printing process.

At Cornell University in the United States, the researchers developed an interactive prototyping system that prints simultaneously as you are creating a design or making any changes. While the design is being printed, the designers can stop the process for any reason they want.

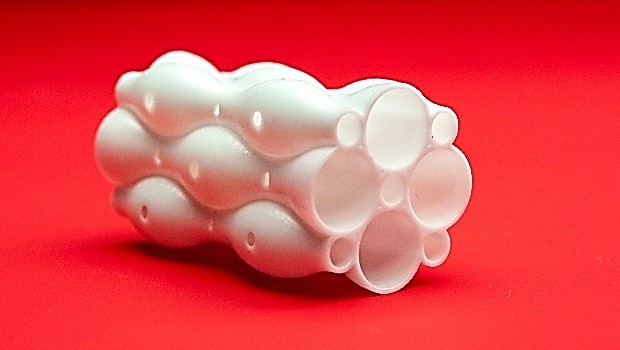

The researchers at Cornell University said that WirePrint technique has been used to create the system. As described in a CAD file, instant-hardening plastic has been extruded by the nozzle that results in creating a wire frame. This wire frame further represents the surface of the solid object.

The technique is created to speed prototyping. Instead of printing the solid, it will shape the object. Therefore, this machine potentially allows the designer to make changes while the printing is in progress.

Speaking of the latest launched printer, it offers “5 degrees of freedom”. However, the nozzle is set to work vertically. But at the same time, stage of the printer can easily be rotated. For instance, in order to add a wing to an airplane fuselage, the printer face can be rotated on its side.

The model also comes with an extended nozzle. It helps in increasing the area of its reach and the changes can be made inside. Also, because of the removable base, you can easily take out the model from the printer for testing or measuring.

The WireFrame is designed by the software and it also sends the instruction to the printer. The designer just needs to focus on the digital model and the printing part is handled by the software. During the interruptions, the printing stops and it is resumed once when the designer is done making changes. That is why all the changes are easily printed in the final product.

This technology has been commenced and because of its pros, we will expect it to reach India very soon. This will help the designers and engineers in India and they can save themselves from the redundant attempts of printing, in case anything needs to be changed in the main design.

Source: The Times Of India Tech