SLA (Stereolithography) & SLS (Selective Laser Sintering) are two widely used 3D Printing technologies in the market today. SLA & SLS both use laser as energy source to bond particles and create 3D objects. The key difference lies in the form of material being used as input.

SLA Process:

SLA is a photo-polymerization process in which a tank of liquid resin is used as input material. The SLA laser travels through the liquid photo-resin, building the part layer by layer. In SLA, a build tray is submerged 0.002 to 0.006 in (0.05 to 0.15 mm) in a basin of liquid photosensitive material. This depth can vary based on laser strength, material, or tolerance desired. A UV laser (not lamp) solidifies one slice of the part onto the build tray. The tray then submerges, another 0.002 to 0.006 in., and the laser solidifies the next slice of the part. The thickness of the layers can affect the quality of print and tolerances. An industry average tolerance is around 3.9 × 10-3in. (0.1 mm). The laser travels the entire path of the part’s cross-section as it builds up each layer, so speed becomes an important consideration.

SLS Process:

SLS is a selective laser sintering process where layers of powder are sintered using high power laser to create the desired object. In SLS, a layer of powdered material is carefully laid down by a leveler or roller on the build tray. A laser then sinters the cross-section of the part. Subsequently, the tray drops another 0.002 to 0.004 in. (0.05 to 0.10 mm) and the process repeats. Similar to SLA, layer thickness varies based on laser strength, material, or tolerance desired.

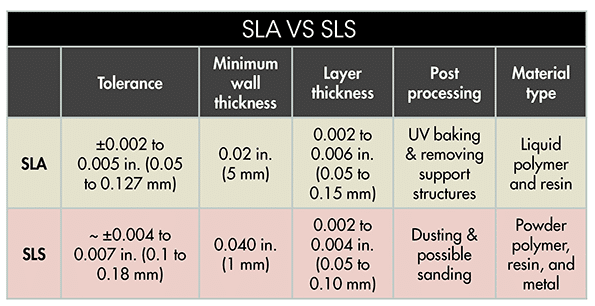

SLA vs SLS

One major difference between SLA & SLS is the material selection. SLA works with photo-sensitive resins & photo-polymers. SLS works with few polymers like Nylon, Polystrene and can also handle metals like Titanium, Maraging Steel, Aluminium. SLA works with liquids whereas SLS works with powder particles that raises safety concerns.

At think3D, we offer services in both SLA & SLS. You can send an email to info@think3d.in or call us at +91-8142896564 to avail our services.