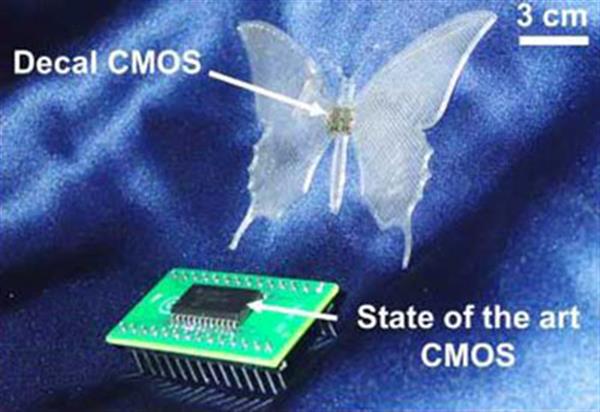

Electronic decals of the Internet of Things can now be 3D printed using advanced nanofabrication techniques. Researchers at the Saudi Arabia’s King Abdullah University of Science and Technology have come up with this new technology which involves 3D printed CMOS circuits.

Stickers have always served decorative purposes for kids and have lesser use for adults. The KAUST university scientists have devised these silicon-based films to accommodate the tiny circuits. These can then be stuck to surfaces for IoT applications. The additive manufacturing techniques were applied to create flexible and high-performance electronic circuits for the IoT. These 3D printed stickers can be used like RFID tags, but with greater use and functionality.

The researchers used technologies like photolithography, patterning, and deposition on a low-cost silicon substrate. They applied these film-like electronics into silicon and then packaged them using a 3D printer into soft substrates. These decal electronics have a high throughput and the circuits continue to show consistent performance even after packaging and flexing.

This printing technique comprises of three components-

• 3D printing for the packaging

• Inkjet printing of silver nanoparticle

• Roll-to-roll platform for printing the decals onto surfaces

With this technique, we no longer need solid cases to house electronics. Flexible packaged ‘low’ cost stickers are easily able to maintain the characteristics of the electronics. Galo Torres Sevilla, a researcher said that this technology opens multiple opportunities for applications where current printed electronics are deficient in meeting the performance expectations.

The research team is now working to transform all kinds of highly complex circuits into decal electronics. Muhammad Mustafa Hussain, an Associate Professor of Electrical Engineering at KAUST, said that the inclusion of a flexible power source would be a great challenge, and the team is working on a flexible solid-state battery to achieve the task.

Source: 3ders.org