From the articles listed here, it is very clear that 3D printing is impacting industries in a big way. But in this article I plan to bring before you an industry that 3D printing technology has been unable to live up to the expectations- Nano Manufacturing. With that being said, the scientists at the Northeastern University have unveiled a printer named NanoOPS printer which is expected to be the game changer in the field of Nano manufacturing.

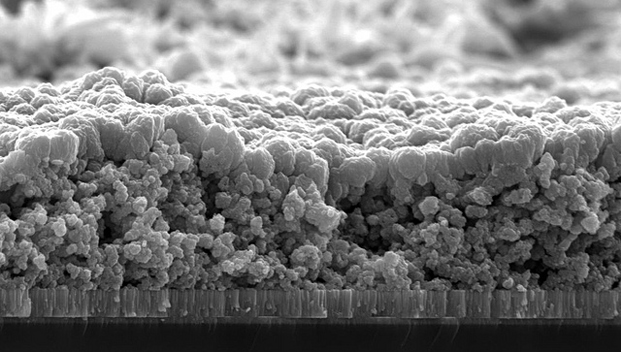

The printer has the potential to 3D print layers which are as thin as 20 nanometers (in physical terms four thousand times thinner than an average human hair). The refreshing thing about this printer is that there are no extruders. The team has developed a new technique known as the ‘directed assembly’. In order to procure a printout from this machine there are a few basic steps that need to be followed.

- Create a mold

- Coat the mold with thin layers of nanowires

- Introduce to electricity (attracting a layer of Nanoparticle)

- Final product

The printer is not restricted to metals and can be used on any kind of Nanoparticle irrespective of the element’s factor. The team feels that the machine could bring down the cost of manufacturing to a great extent. The director of Northeastern’s Center for High-rate Nanomanufacturing (CHN), Professor Ahmed Busnaina, said, “What we have developed at our center is a system that’s like newspaper printing or printing money, where you have a big plate, you put ink on it, and bang: One hit, you’re done. Only here, the ink is made of very small and sensitive nanoparticles attracted to the template using electrophoresis, so we have to pick exact dimensions and materials. We put a template with a pattern represented by nanowires into a solution that is similar to ink, but very dilute. Then we apply a couple of volts so that nanoparticles in the ink are drawn to the nanowires. Then we take out the template and transfer the assembled nanoparticles to a surface of either a hard or flexible substrate. That would be the first layer of a device, which takes about a minute or two. A sensor may have just a few layers, where advanced electronics may have 10 layers or more.”

The project was funded by National Science Foundation and the Massachusetts Technology Collaborative, with $24.5 million and $7 million from each. The team has decided to price tag the printer with a lump sum amount of $1 to $1.5 million.

source: http://3dprintingindustry.com/2014/09/19/3d-nanoparticle-printer-unveiled-northeastern-university/