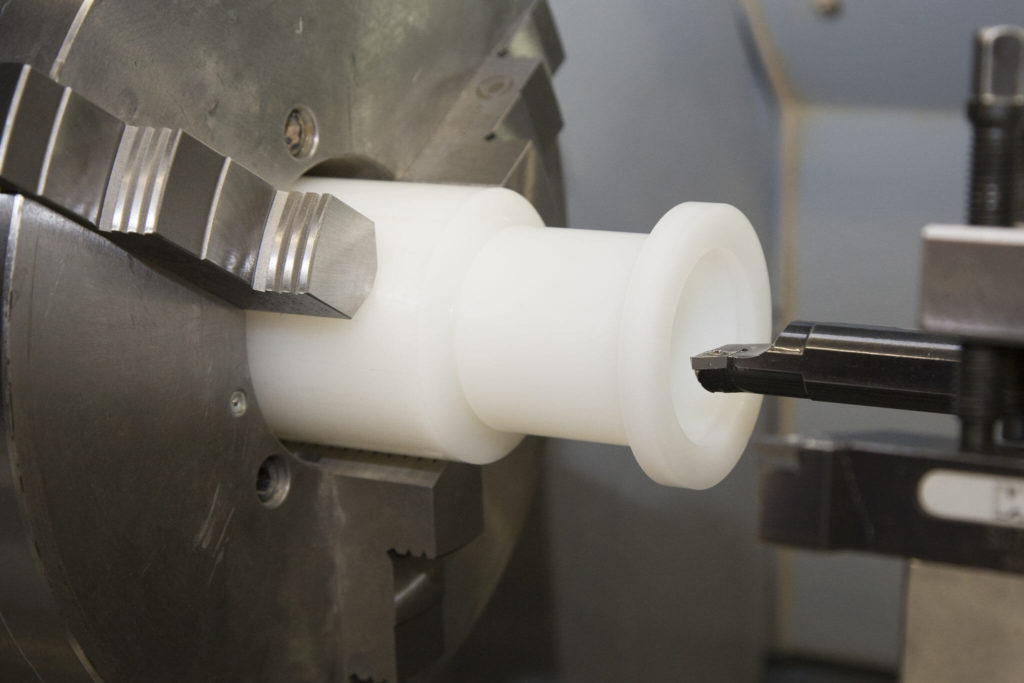

CNC Machining is the most commonly used process to manufacture products in both metals and plastics. In this article, we shall look at various commonly used materials for CNC Machining. Below is the list of most commonly used plastic materials for CNC Machining.

- ABS

- Nylon 6/6

- Acrylic

- Delrin

- HDPE

- Polycarbonate

ABS Plastic:

Overview: ABS plastic is the most widely used plastic material. It offers high impact strength, electrical resistance and toughness at a low price. It is very easy to be machined and can be readily painted, glued or welded together.

Benefits: ABS plastic is excellent choice for general purpose prototyping, pre-molding prototypes, parts that receive impact and require toughness or when low cost is desired.

Drawbacks: ABS plastic doesn’t have good abrasion or chemical resistance and will melt in acetone. It is also not a super strong plastic material.

Common Applications: The most common application is to make electronic enclosures, keypads, household appliances.

Nylon 6/6:

Overview: Nylon is a strong durable plastic applicable to a wide variety of purposes.

Benefits: Nylon has high strength and rigidity that it maintains over a wide temperature range, good electrical insulation and good chemical & wear resistance. Nylon is a good choice for applications in which strong, durable parts are needed at low cost.

Drawbacks: Nylon 6/6 absorbs moisture causing it to swell and lose some dimensional accuracy. It can also warp if there is a large amount of asymmetric material removal during machining due to internal stresses inherent in the material.

Applications: Nylon is most commonly found in medical devices, circuit board mounting hardware, automobile engine compartment components and zip ties. In many of these applications it is used as an economical alternative to metals.

Acrylic

Overview: Acrylic, also known as Plexiglass is the tradename for PMMA plastic. It is tough with decent impact strength and scratch resistance and can be easily glued with acrylic cement.

Benefits: It is well suited for applications that require optical transparency or translucence or as a less durable but cheaper alternative to Polycarbonate.

Drawbacks: Acrylic is a brittle plastic and will fail by cracking or shattering rather than by stretching. Any machined surface on piece of acrylic will lose its transparency and take on a frosted translucent appearance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.