What is Stereolithography (SLA)

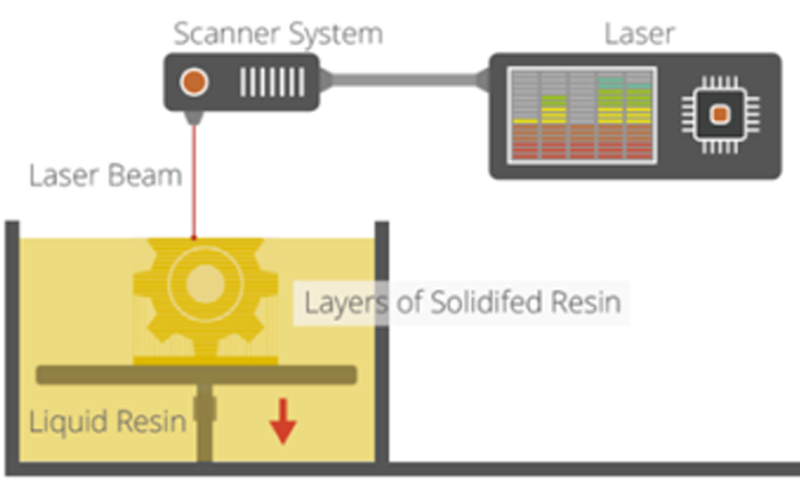

Stereolithography or Stereolithography Apparatus (commonly referred as SLA) is an additive manufacturing process that belongs to the Vat Photopolymerization family. In SLA, an object is created by selectively curing a polymer resin layer-by-layer using an ultraviolet (UV) laser beam. The materials used in SLA are photosensitive thermoset polymers that come in a liquid form. Stereolithography was developed in 1986 by Chuck Hull when he patented the process and also cofounded 3D Systems, world’s first 3D printing company.

SLA has many common characteristics with Direct Light Processing (DLP), another Vat Photopolymerization 3D printing technology. For simplicity, the two technologies can be treated as equal.

A laser beam is directed in the X-Y axes across the surface of the resin according to the 3D data supplied to the machine (the .stl file), whereby the resin hardens precisely where the laser hits the surface. Once the layer is completed, the platform within the vat drops down by a fraction (in the Z axis) and the subsequent layer is traced out by the laser. The resin that is not touched by the laser remains in the vat and can be reused. This continues until the entire object is completed and the platform can be raised out of the vat for removal.

Support structure is always required in SLA. Support structures are printed in the same material as the part and must be manually removed after printing. The orientation of the part determines the location and amount of support. It is recommended that the part is oriented so that so visually critical surfaces do not come in contact with the support structures

Design and Slicing Process

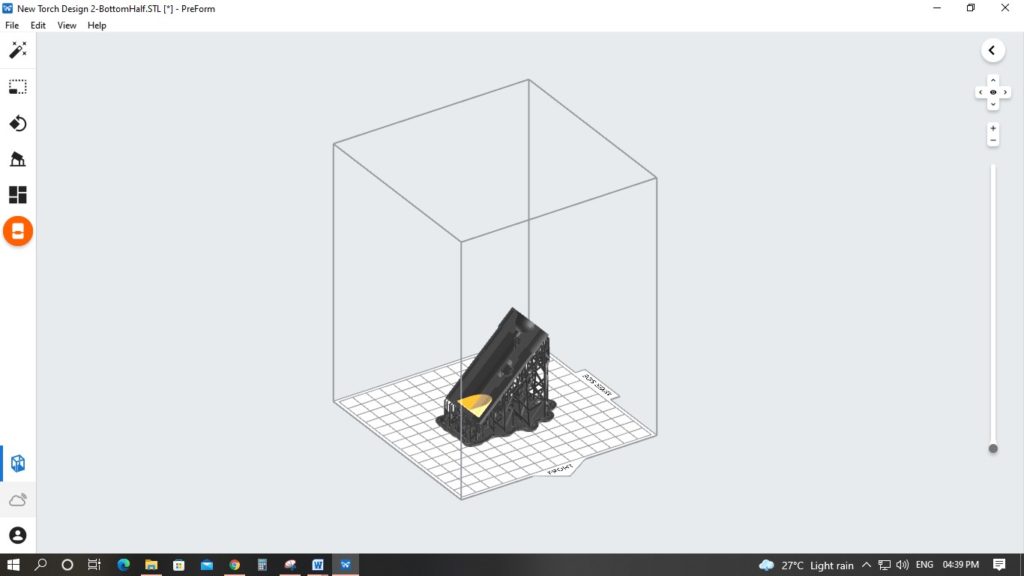

The CAD Model is developed using any 3D Design softwares like Solidworks, CATIA, NX, Fusion 360 etc. and the model is exported in STL file format. The Slicers that are dedicated for SLA printing convert the STL file into individual layer patterns that instruct the laser light reflector to direct the UV light to fill the outline area of each sliced layer. It is recommended to use the Slicer software that comes with the printer manufacturer.

Design Guidelines

Minimum Wall Thickness: 1.2mm required

Fine Details: Text should at least be 2 mm in size and 0.5 mm in depth. Holes should at least be 2 mm in diameter

Layer Resolution: 0.05 mm to 0.3 mm

Accuracy: ± 0.15% (with lower limit on ± 0.1 mm). XY accuracy of 25 to 50 microns is possible.

Maximum Dimensions: 300 mm x 200 mm x 300 mm

Fig. PreForm slicer for Formlabs Form 3 printer

Post Processing:

SLA printed parts are required to be washed in Iso Propyl Alcohol to remove any excess resin stains on the model and then the part is gently rinsed in water.

Fig. Washing process in containers of Iso Propyl Alcohol and Water.

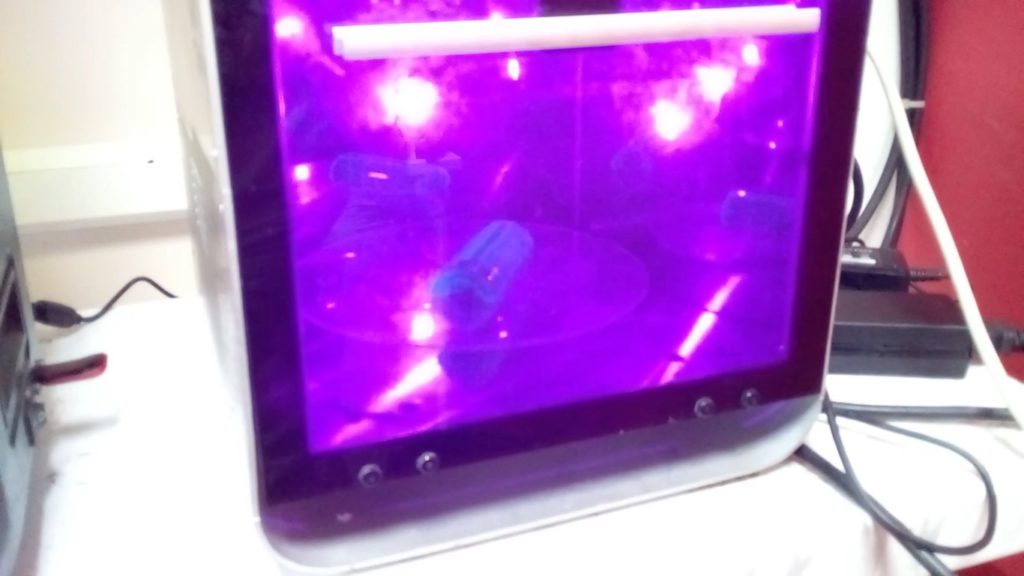

The part is then placed in a UV lamp for 20 minutes to further strengthen the part. Part tensile strength increases by 30% after post curing under UV lamp. Dedicated UV lamp enclosures are available that rotate the part 360 degrees to cure the part in all directions.

Fig. Part being post cured under UV Lamp

Materials

There are a wide range of UV curable resins available and can be classified into 4 categories (General Purpose, Engineering, Dental and Jewelry). Material properties of some resins are given below.

General Purpose: Clear and Coloured Resins have Ultimate Tensile Strength of 23 MPa.

Engineering Grades

• Rigid – Rigid10k resin has Ultimate Tensile Strength of 65MPa after post-curing

• Tough and Durable – Tough2000 resin has Ultimate Tensile Strength of 46MPa after post-curing and a Flexural Strength of 65 MPa.

• Flexible and Elastic – Flexible 80A has Ultimate Tensile Strength of 8.9 MPa, 3.1 MPa at 50% elongation

Fig. SLA 3D Printed Parts out of Clear, Flexible, Rigid and Tough Material resins

Applications

Modelling

SLA printing is best for craftsman models, scale models characters and miniature printing for displays, gaming, film and animation industries due to the high dimensional accuracy.

Product Design:

With dimensional accuracy almost on par with injection molded parts any new product concept can be tested and validated with SLA printed parts. They can also be used for creating master patterns for silicone molding or vacuum casting.

Jewelry Industry:

Jewelry items can be directly printed with SLA printers with wide range of resins and colors, Master patterns can be made which can then be used to create the mold cavities for metal jewels.

Fig. Jewelry designs

Molded Parts

Master patterns for vacuum casting and vacuum molding of packaging trays can be printed in SLA. Mold inserts can be 3D Printed instead of needing to machine the whole mold and can be used for injection molding. Rigid10k resin prints are capable of withstanding up to 1000 shot cycles creating more opportunities to produce early market production parts.

Fig. White- SLA printed mold Insert. Red injection molded parts that came out of the mold.

Dentistry

Dentures is another important area where stereolithography plays its role. Scanned rims of the patient can be converted into CAD models and both Denture Teeth (Artificial Teeth) and Denture Base (Soft tissue that holds the teeth) can be directly printed.

Fig. Dental Applications

Advantages Of Stereolithography

Stereolithography method is capable of producing most dimensionally accurate parts down to 25 micrometers. High quality surface finish (Ra value) of as low as 0.4 to 2 micrometres can be achieved.

Limitations Of Stereolithography

Build Volume of SLA printers is limited to 300 x 200 x 300 mm. Common plastics like PP, PC, HDPE and PLA cannot be printed in SLA. SLA printers are costlier than FDM style printers.

For more information on our services, please visit our services page: https://www.think3d.in/services/3d-printing/stereolithography