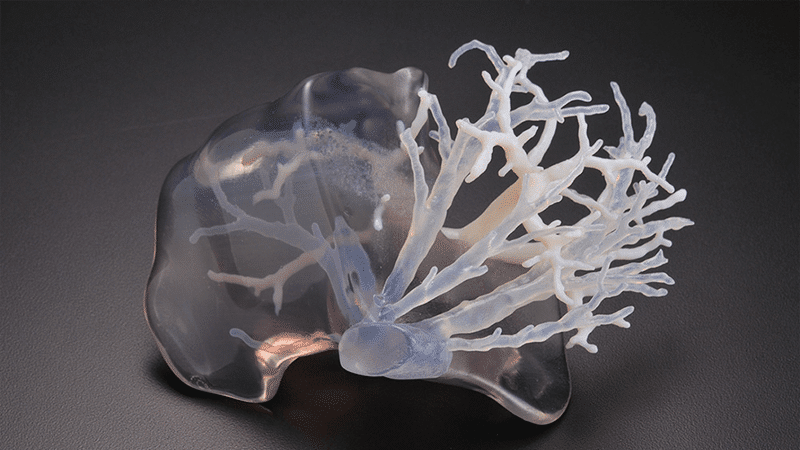

PolyJet offers the unique ability to print parts of multiple materials and colors, with different mechanical or physical properties, all in a single build, there by opening up numerous combinations of prototyping materials.

WHY CHOOSE THINK3D

think3D has one PJP( Poly Jet Printing) machine in-house to offer the unique ability to print parts of multiple materials and colors, with different mechanical or physical properties.

Polyjet process is a very precise 3D printing method, producing accurate parts with a very smooth finish. The nature of this product allows for the simultaneous deposition of a range of materials, which means that a single part can be produced from multiple materials with different characteristics and properties.

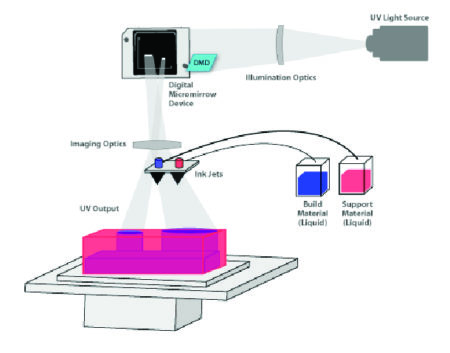

PolyJet works by jetting photopolyme r materials in ultra-thin layers onto a build platform selectively through multiple jet heads (with others simultaneously jetting support materials where required). Each photopolymer layer is cured by UV light immediately after it is jetted, producing fully cured models that can be handled and used immediately, without post-curing. The gel-like support material, designed to support complicated geometries, is subsequently removed by water jetting.

r materials in ultra-thin layers onto a build platform selectively through multiple jet heads (with others simultaneously jetting support materials where required). Each photopolymer layer is cured by UV light immediately after it is jetted, producing fully cured models that can be handled and used immediately, without post-curing. The gel-like support material, designed to support complicated geometries, is subsequently removed by water jetting.

The Jet technology enables horizontal layers of just 16 µm (0.0006″), fine details, and ultra-thin walls down to 0.6 mm (0.024″) depending on the geometry of the part. That means PolyJet is capable of building very precise mechanical components, offering you high-quality prototypes for a shorter time to market.

-

Master copies for vacuum casting and other low volume prototyping techniques

-

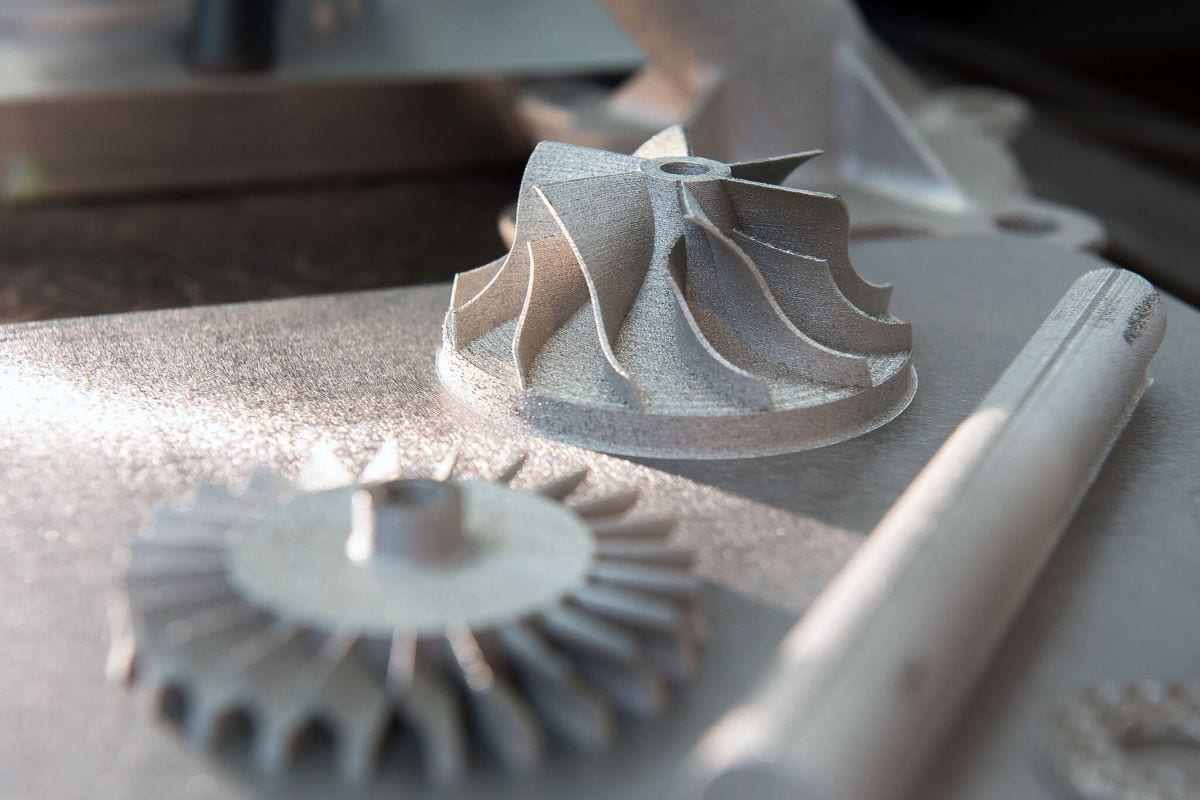

Patterns for investment casting

-

Tooling patterns

-

Functional testing prototypes

-

Dental/ jewelry/ art and other sectors which require high detailing and finish

-

Parts to match specific Shore A values

- Multi-color, multi-material parts

Vero White

| Tensile Strength | Flexural Strength | Heat Deflection Temperature @0.45 MPa | Impact Strength | Hardness (D) |

| 58 | 93 | 48 | 25 | 85 |

Rigur

| Tensile Strength | Flexural Strength | Heat Deflection Temperature @0.45 MPa | Impact Strength | Hardness (D) |

| 40 – 45 | 52 – 59 | 49 – 54 | 30 – 35 | 80 – 84 |

Polyjet flex

| Tensile Strength | Flexural Strength | Heat Deflection Temperature @0.45 MPa | Impact Strength | Hardness (D) |

| 0.8 – 1.5 | NA | NA | NA | 26 – 28 |

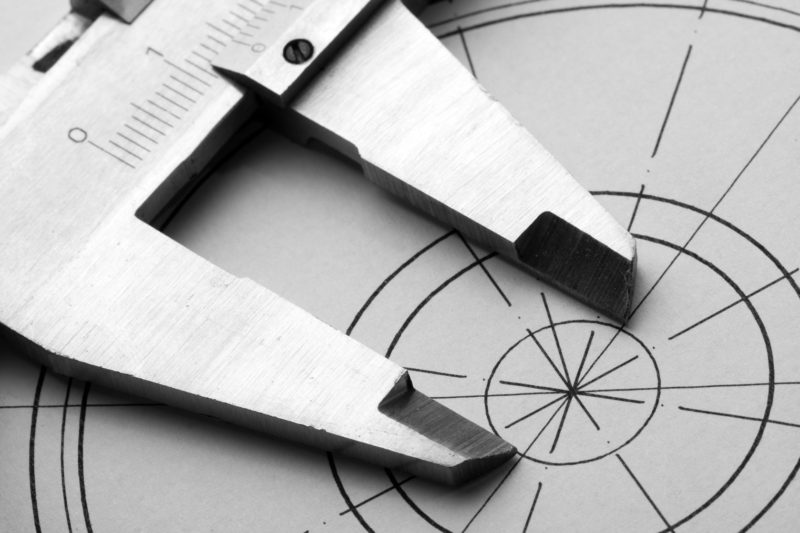

Minimum Wall thickness: 0.8 mm

Minimum details size: 2 mm (for text/ hole diameters etc)

Layer thickness: 0.01 mm

Max dimensions: 260 x 200 x 200 mm

Standard Accuracy: ± 0.2% (with lower limit on ± 0.2 mm).

Lead Time: Minimum 4 working days for despatch

Surface finish: Smooth outer surface, which can be further enhanced

Basic: Support cleaning, Curing, Smoothing

Add on: Primer, Coating/ Painting