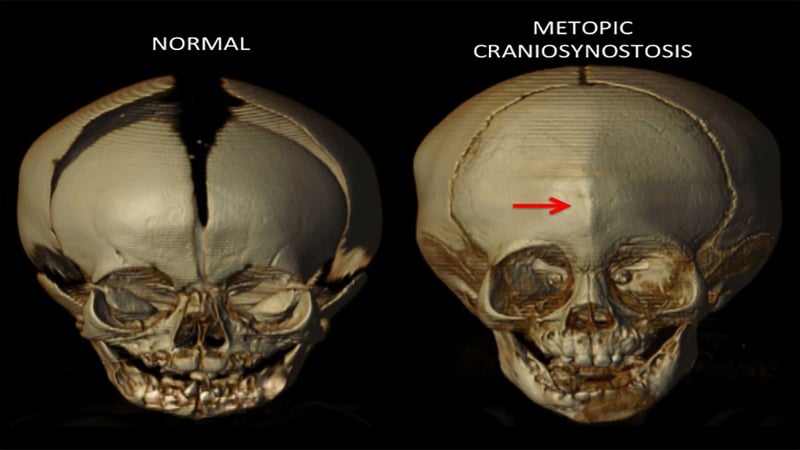

Advances in 3D printing are capturing attention in the medical field. Recently an infant in Delhi, suffered from Trigonocephaly treated with the help of additive manufacturing. Trigonocephaly is a congenital condition of premature fusion of the metopic suture leading to a triangular forehead, which causes neurological issues in addition to looking abnormal. With the help of additive manufacturing, the surgeons at Fortis Hospital in Shalimar Bagh, Delhi, have been able to develop a model on the skull with various components.

Generally the bones forming the skull are separated by joints called sutures, which also serve as centres of growth,”said Richie Gupta, who specializes in reconstructive surgery at the hospital. These sutures fuse at set times after birth, the metopic suture obliterates between 3-9 months of age. Early sutural fusion results in lack of skull growth. But still the brain grows at a rapid rate during this period. People who are suffering with this will have an early suture fusion and need to be diagnosed.

The main aim behind the manufacturing of the 3D printed skull is to enable surgical planning of the delicate procedure, which if unsuccessful could be detrimental to the patient’s health. “We worked on those to determine the exact size of the bony cuts on the patient’s skull,”said Dr Sonal Gupta, director, neuro and spine surgery at the hospital. Even the smallest deviations can cause blindness, profuse bleeding or even brain damage. We conducted a mock surgery on one of the 3D models in order to know the exact measurements. So we transferred these measurements from 3D models to the patient’s skull.

“With the help of the 3D models we have become successful in our execution, reducing the operative time and allowing the actual surgery to be precise” said Gupta. Finally the surgery was completed in 7 hours, and the patient was sent to the ICU for 2 days and provided with post-surgery care. The patient was discharged on the 6th day and he recovered, thus ending another successful story with the help of 3D printing.

Image Source : 3dprinting