Tag: Italy

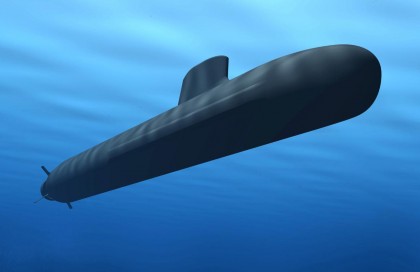

3D printed low cost submarines can be used in deep sea explorations – Deep-Z team proves it.

June 15, 2015

No Comments

Read More »

Barilla believes that traditional pasta lovers will start liking his 3D printed pasta

May 6, 2015

No Comments

Read More »