We all are aware of additive and subtractive manufacturing. CNC machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. In order to make the production parts, the tool moves in different directions. So based on the movements its axes are categorized as 3,4, 5-axis. Now let us know about them in detail.

How does a CNC machine move?

First, we need to find out which axis is which? For suppose if you are standing in front of a CNC mill, the X-axis will be parallel and moves left and right. Y-axis is perpendicular moving forward and back, Z-axis is vertical from your reference point. Generally, the workpiece moves on the X/Y plane. The main task of the spindle is to hold the workpiece and move it along the Z-axis.

What is a 3-axis mill used for ?

3-axis machines are used for a variety of milling operations. These are mainly used for making flat or planar surfaces. It can only move along the z-axis because the spindle cannot enter the workpiece from the side. Also it can make rounded profiles such as to drill and tap holes. This is a limitation for many parts but this can be overcomed by repositioning the workpiece. Actually this is a slow process so we avoid this most of the time. So this can make circular profiles that too on the X/Y plane.

What are the Advantages of 4 axis CNC mill ?

With the help of 4 axes, we can add rotary motion along the X-axis. So this opens up new possibilities. The main task of the rotary table is to rotate the workpiece so that the remaining sides are also accessed easily. So by using these 4 axis we can avoid the problem of re-mounting which we faced in 3 axes. It is now possible to drill holes or to penetrate completely through a part. We can create even complex profiles easily with this rotary feature.

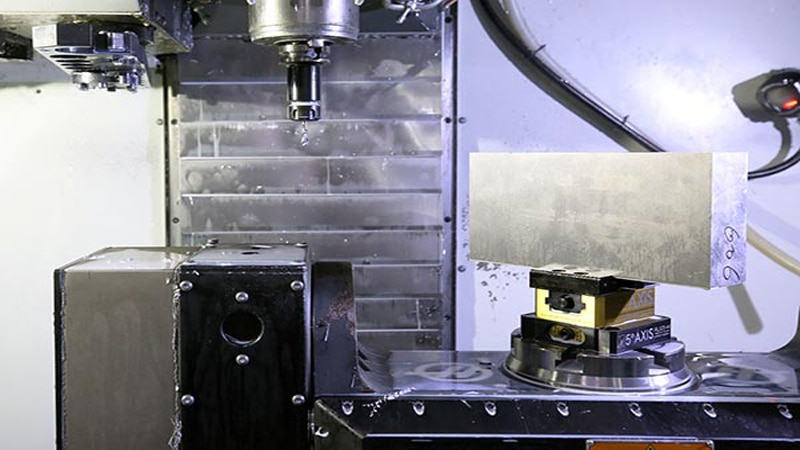

What are the Advantages of 5 axis CNC mill?

This time we have added another feature that is y-axis rotation. Rotation around Y is called the B axis. In order to achieve five axes freedom, the 3 axis mill should be retrofitted with a trammel head. This provides motion along the A and B axes. We can make complex shapes such as helical rotors only with the help of a 5 axis machine. A 5-axis machine is more rigid when compared with others and should maintain accuracy because it moves simultaneously in different directions.

How many more axes are there?

In order to make more sophisticated parts, CNC machining centers are trying to make 9 axes machines.