A 32-year old psychologist Richard Stratton was implanted a 3D printed titanium jaw, the first of its kind, in an operation in Melbourne, Australia. A part of Stratton’s jaw was missing as it had not grown properly due to an injury in school, which included a joint to the skull called condyle. He suffered immense pain in his mouth while eating or moving his jaw.

Dr. George Dimitroulis, an oral and maxillofacial surgeon, designed a prosthetic jaw, along with the mechanical engineering team of the Melbourne University. Though jaw replacement surgeries are performed all around the world, it is the first of its kind as it uses a 3D printed titanium jaw part and a plastic jaw joint. His joint is called the temporomandibular joint and was incorporated in plastic to protect the skull from corrosion with metal points.

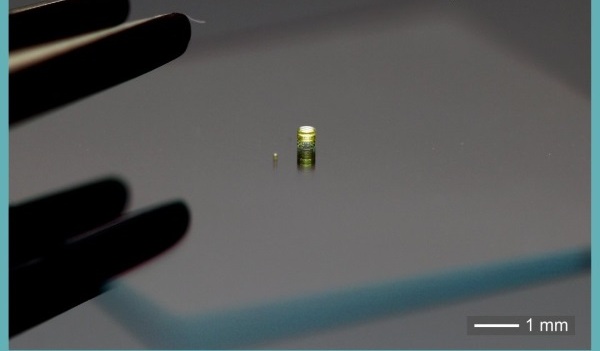

3D Medical, a Port Melbourne firm 3D printed this jaw using powdered titanium that was heated and placed layer by layer. CT scan images of Stratton’s skull were done and a plastic model of his skull was made to test and make the titanium fit perfectly. This part was manufactured in New Zealand but in future, the parts will be indigenously manufactured in Australia. The chairman of the company, Dr. Nigel Finch said that since it was the first time, about 30 customized parts of the jaw were printed, but it will be easier in future.

Dr. Finch further went on to say that with the successful adaptation of this technology in hospital and other healthcare systems, the design and manufacturing costs of these parts would become very cost effective.

Melbourne University biomedical engineer, Dr. David Ackland, said that the prosthetic had to be tested several times before implantation to see how a foreign body would adjust in the human body environment. Computer simulations were performed to see the impact on the joint and the jaw implant and actions like chewing and biting were initiated for testing.

The 5-hour long operation was a success and Dr. Diimitroulis said that the 3 years of labor and efforts had paid and paved a path for future 3D printed implants.

Source: abc.net.au