ABSTRACT:

Presentation plays a vital role to obtain the Clients and Customers. A Functional Prototype adds an extra advantage to the presentation. Such prototypes can be made comfortably with 3D Printing. As a part of Presentation we have Client with a requirement of a Functional Prototype of Transformer with IoT integration. Transformer is to be 3D Printed which illustrate the components like Core, Winding, Coolant, Insulation, Bushing etc.The entire project was approached as a full-time endeavour. Designing, Manufacturing, Assembly and Testing was undertaken by Think3D Labs, AMTZ campus, Visakhapatnam.

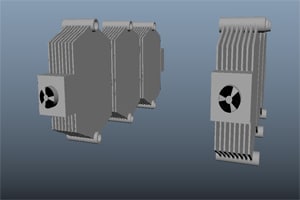

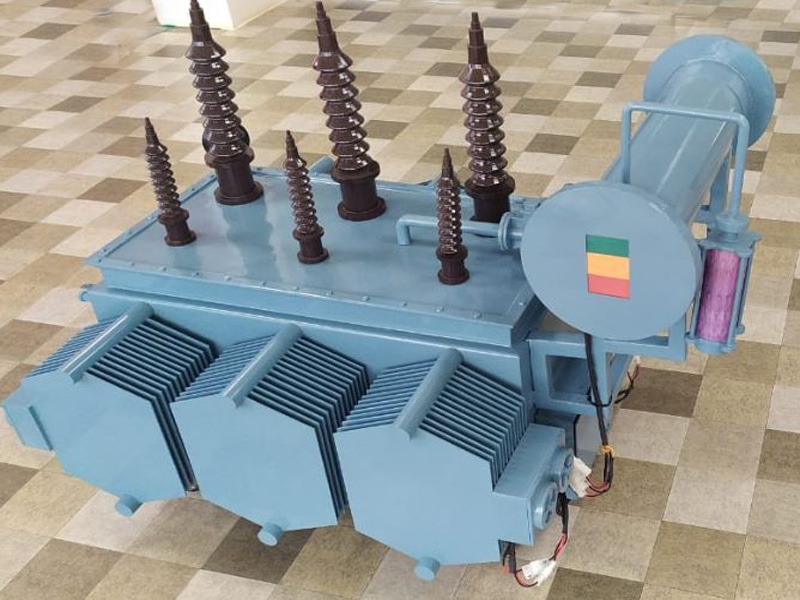

A 3D design is designed by taking sample images and videos as reference. The components are manufactured with the help of Additive Manufacturing, Sheet Metal Fabrication and Laser Cutting technologies. The requirements of the Prototype, Internal Armature Winding block should be draggable. Red, Yellow, Green color indicator on cylinder with working. Dial gauges for temperature indication and detachable components like drain valve, conservator, radiators etc.

This report covers a broad range of engineering disciplines. The root of the system is mechanical design, manufacture and computerize for a Functional Prototype. The electronics made the prototype functional whereas micro controller and programming allow for control schemes.

INTRODUCTION:

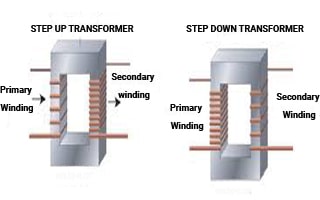

A Transformer is a passive electrical device that transfers electrical energy from one electrical circuit to one or more circuits. A varying current in any one coil of the transformer produces a varying magnetic flux, which, in turn, induces a varying electromotive force across any other coils wound around the same core. Electrical energy can be transferred between the (possibly many) coils, without a metallic connection between the two circuits. Faraday’s law of induction discovered in 1831 described the induced voltage effect in any coil due to changing magnetic flux encircled by the coil.

Classification of Transformer

- Power rating

- Duty of a transformer

- Frequency range

- Cooling type

- Voltage class

- Constant-potential transformer descriptor

- Basic magnetic form

Constant-Potential Transformer Descriptor

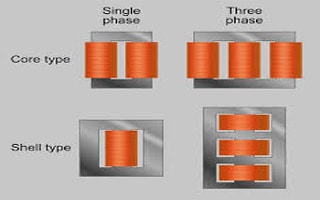

Basic Magnetic Form

Cooling Type

Applications

- The transformer used for impedance matching.

- The transformer used for isolate two circuits electrically.

- The transformer used in voltmeter, ammeters, protective relay etc.

- The transformer used in rectifier.

- It is used in voltage regulators, voltage stabilizers, power supplies etc.

DESIGNING:

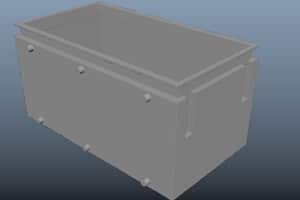

The Design for manufacturing of outer body, interior components like cores, windings, insulation and bushing is designed according to the desired prototype.

DESIGN 1 :

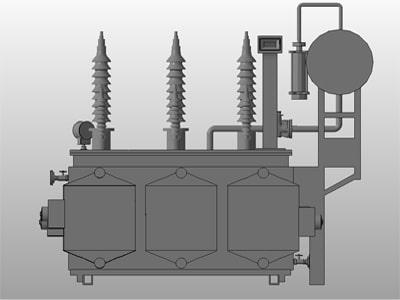

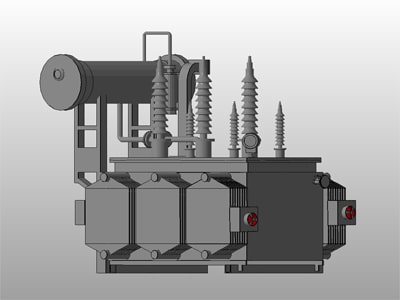

All the individual components are designed separately with the desired measurements.

Outer Body

Conservator

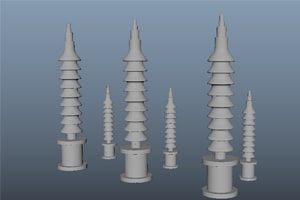

High and Low Voltage Bushings

Radiate fans

DESIGN 2 :(Assembly)

Front-View of Assembly Design

Isometric-View of Assembly Design

MANUFACTURING:

The Manufacturing of Outer body is done with sheet metal fabrication, laser cutting of acrylic sheets. The components like High and Low voltage bushings are manufactured in Additive Manufacturing technology. 3 Armatures(burnt, semi burnt, new coil) are placed with copper windings to represent the damages in armature. Internal armature winding block is placed on a rail for dragging out and placing in. Dial gauges are attached to show the temperature inside the block,radiate fans and fins are attached to cool down the equipment. Red, Green and Orange led lights are installed to indicate the oil levels in the conservator. Raspberry Pie micro controller and coding is used for the controlling of desired functioning. After the complete manufacturing of the components, they have undergone for painting. Later on they are assembled accordingly with the design.

Final Prototype Indicating Conservator level

Temperature Indication with Thermal Gauges

CONCLUSION :

Ultimately we have manufactured the desired prototype in the span of 15 days. The experience we have in the previous miniature models with IoT integration made our job comfortable. The objective and assurance of this project have been achieved. It is anticipated that our sincere and innovative efforts that is presented will acquire us several new projects to be researched in the future.