Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) are two Rapid Prototyping Technologies belong to the Powder BED Fusion category. The build materials in these technologies are thermoplastic polymers(namely Nylon) which is in granular form. In both of these, the build materials are fabricated as layer-by-layer technique with thermally fusing polymer.

The main difference between MJF and SLS is the heat source. MJF uses Infrared light where as SLS uses CO2 laser. Also in SLS each cross section is fused point by point, where as in MJf fusing takes place line-wise method. There are many other differences between these technologies with respect of accuracy, materials, cost and workflow.

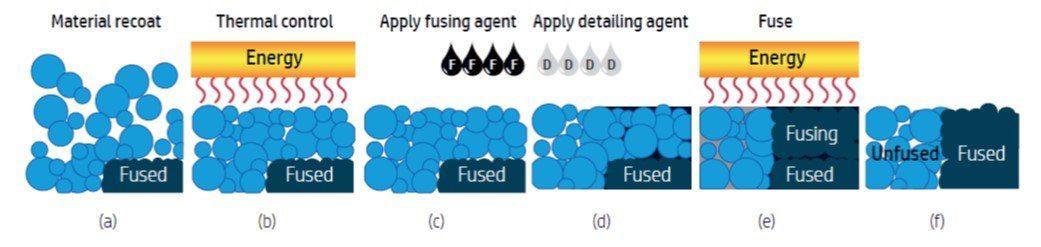

Multi Jet Fusion (MJF) is an integration of Powder Bed Fusion and Binder Jetting techniques. In MJF, a thin layer of thermoplastic polymer powder is spread over the build bed and heated to sintering temperature. The Fusing agent is deposited on the powder with the help of a carriage with inkjet nozzles travels over the bed. At the same moment detailing agent is also lay down that enhances the edges of the part to be fine detailed and smooth surfaces. These areas are exposed to the high power IR energy, it causes agents and material to selectively fused while leaving the rest of the build material. It is repeated until all parts are build.

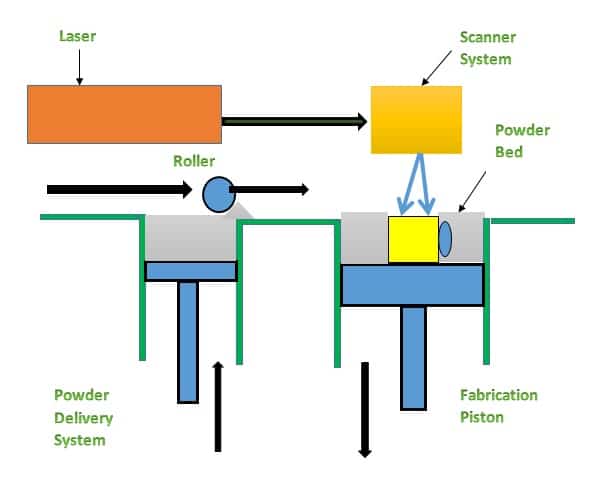

Selective Laser Sintering (SLS) is a rapid prototyping technique that uses a laser likely CO2 laser as the power source to sinter powdered material namely polyamide and polystyrene powders, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

In SLS technique nylon is used as build material. In this technique, the build material will be in powder state. This powder is fused selectively by a laser according to the data given at the time of design.

| Property | Multi Jet fusion(MJF) | Selective Laser Sintering(SLS) |

|---|---|---|

| Build/Bed Volume | 380 x 284 x 380 mm | 200 x 250 x 330 mm |

| Layer Thickness | 0.08 mm | 0.06-0.12 mm |

| Accuracy | ±200 microns | ±100 microns |

| Optical Appearance | Light Grey | White |

| Cost | Comparatively low cost | Comparatively high cost |

| Post Processing | Dusting, possible sanding, cyano-acrylate coating as per requirements | rapid cooling, removal of loose powder by vacuum, bead blasting, primer finish |

| Applications | Non-Cosmetic housing, Covers, Wiring Clips, Guides and Grommets etc. | Aerospace hardware, Medical & Health care, Injection molds Inserts etc. |

Sample Parts

Multi Jet Fusion

Selective Laser Sintering