Differences in Principle and Procedure

Principle

Color Jet Printing(CJP) is Powder based additive manufacturing technique that follows a Principle of Binder Jetting. In Binder Jetting, the two essential components are core and binder. A binder is selectively deposited onto the powder bed, that binds the core material of those areas together to form a 3D object one layer after the other. The materials very often used in Binder Jetting are metals, sand and ceramics that are in granular form.

Poly Jet Printing(PJP) is one of the resin based 3D printing technologies in which the Principle is Material Jetting. Material Jetting is a rapid prototyping technique that operates in a similar mode of 2D printers. In Material Jetting, a printhead dispenses droplets of a photo-responsive resin that solidifies under UV light that builds a part layer by layer. The build materials used in this technology are Thermoset PhotoPolymers usually in liquid form.

Working Procedure

Color Jet Printing (CJP) is an additive manufacturing technology which comprises two essential components – core and binder. With a help of roller, the Core material is spread all over the build platform as a thin layers. After spreading of each layer, an inkjet print head deposits the color binder according to shape of the prototype, this tends to bind the core material and gets solidify. The build platform steps down one layer,successive layers are spread and printed, which results to fabricate required 3-dimensional model. After completion of the model, unbound powder is automatically removed by vacuuming.Post-Processing can be done with salt water cure, wax cure, color bond based on the requirements.

Poly Jet Printing(PJP) is a rapid prototyping technology, the prototype is build by jetting head and UV light. The Material Jetting head deposits a single layer of the photo-sensitive polymer by gliding horizontally. The depth of individual layer of photo-polymer deposited by each jetting head is selectively directed by software.As soon as the liquid photo-polymer resin droplets are sprayed from multi-nozzle print head, they are immediately cured and hardened by an UV light. Once a layer is completed,the build platform moves vertically down by one layer, next layer of build material is ejected from jetting head and cured by UV light. The sequence of above process is continued until the prototype is build.

Differences in Properties

| Property | Color Jet Printing(CJP) | Poly Jet Printing(PJP) |

|---|---|---|

| Build/Bed Volume | 254 x 381 x 203 mm | 255 x 252 x 200 mm |

| Layer Thickness | 0.06 – 0.08 mm | 0.1 – 0.3 mm |

| Accuracy | ±10 microns | ±30 microns |

| Post Processing | Salt water cure, Wax cure, Color bond etc. | Sanding, Lacquering of veroclear etc. |

| Limitations | Porous, unfinished surfaces, residual defects and stress | Sharp edges are slightly rounded, support material creates alternations in surface quality |

| Applications | Art, architecture, demonstration model, master patterns etc. | Prototypes for investment casting, multi material prototypes (transparent, non-transparent) etc. |

Sample parts

Color Jet Printing(CJP)

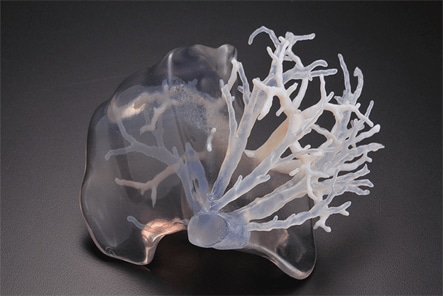

Poly Jet Printing(PJP)