Researchers at Virginia Tech and the Rhode Island School of Design in their attempts to explore concepts in glass design created a robot-based 3D printing process for glass through the nation’s first Collaborative Glass Robotics Laboratory.

Nathan King, an assistant professor of architecture in the Center for Design Research at the Virginia Tech School of Architecture + Design, and Stefanie Pender, a glass artist and faculty member in the Glass Program at the Rhode Island School of Design formed the Glass Robotics Lab in 2013 with the support of the Division of Foundation Studies and the department of Glass at Rhode Island School of Design, Virginia Tech School of Architecture + Design, Center for Design Research and Autodesk.

“The 6-axis glass-printing process was proven in 2013 and has continued to improve. At this point glass printing has caught the attention of several research groups, each making incremental strides, and each with different goals,” King said. “The glass robotics facility is the first of its kind research studio and will house a large custom glass furnace, large format annealing ovens, and will utilize the Design Robotics Studio’s large format industrial robotic arm to support the advancement of the mission to realize new potential in glass through the lens of computational design and digital fabrication processes.” The research studio located at the College of Architecture and Urban Studies’ Research and Demonstration Facility in Blacksburg, Virginia and will be open in Spring.

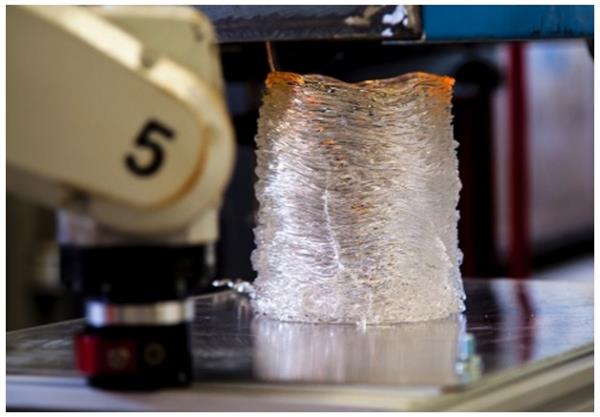

The innovative robotic glass 3D printing method developed by the researchers uses computational design to move the robotic arm fixed to the build plate in particular patterns unlike the regular 3D printing setup where the extruder moves in particular pattern. The molten glass comes out of the extruder continuously as a thin strand on the build plate. The video below shows how the researchers have integrated art, design, technology and science in customized glass fabrication. “Beyond material exploration we are also developing new digital processes that allow real-time robotic motion control thus enhancing the potential to exploit a range of material behavior,” King said.

Pender said. “Instead of a technology-driven approach, we can approach digital fabrication from a place of profound material understanding. This research is evidence that the traditional technical arts will not be replaced by digital fabrication, instead, the technical arts will help to drive and support the direction of future making. By focusing on the integration of the material and the computational, we can discover generative behaviors within the glass material. For example, ‘transient coiling’ is a mode of movement which hot glass fibers rotate as they come into contact with other materials, thus creating volumetric depth from simple planar movements. The ability to highly control the movement of the glass as it is deposited through robotic control reveals an opportunity to manipulate this phenomenon which would be impossible without an automated process – thus presenting a new design potential.”

The researchers are presently focused on exact precision and utmost material control governed by the prescribed computational form and surface finish thereby resulting in new patterns and design opportunities.