The 3D printing industry is on the brink of transforming almost all the sections of our lives and kick start the latest industrial revolution. With the growth in the population index of the world, there is an increase in the problems of finding a shelter for all. As per Maslow’s hierarchy, the basic needs of a person is food, shelter and clothing, we are running short in all the above areas, thanks to rising population. But 3D printing is opening a new door in the sector of providing shelter to all in an express way. Technology seems to be an answer to all the problems that society faces nowadays!

With the technological advancement of 3D printing and contour crafting, being homeless would be something like polio, which has been eradicated. 3D printing promises to revolutionize the way buildings are designed and built. The methods that currently exist in the construction business is labor intensive, slow, dangerous and the budget is often hay wired. There are thousands who are prone to construction hazards whether minor or major. Construction is the only sector where the role of humans is inevitable and also compulsory but now, with the changes that construction industry will encounter with the help of 3d printing will change the face of construction sector forever.

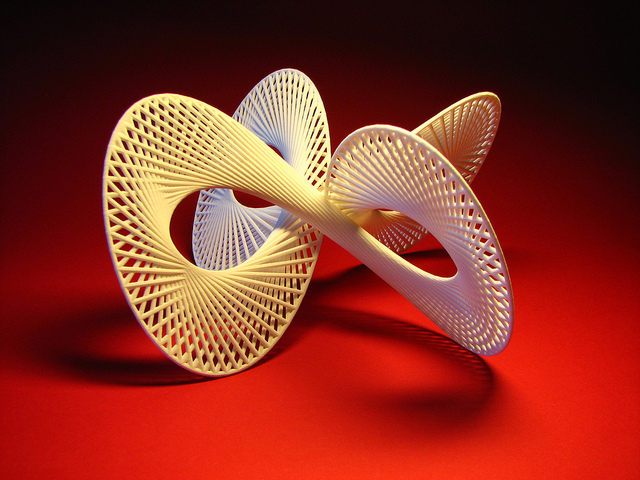

So far, applications of 3D printing in architecture have been restricted to the proto-typing of models and there have been a lot of talks about using this technology in the process of creating habitable structures. An Italian entrepreneur, Enrico Dini was the first person to print a structure on an architectural scale, with the help of enormous “D-Shape printer”. This machine comprises a giant rig that lays down layers of sand, onto which a row of nozzles linked to CAD software deposits a binding agent that solidifies the sand and it is transformed into a type of artificial sandstone. The problems with this machine is that the material it uses is very fragile and breakdown easily. The other problem with the printer is that the feeding system of the printer is not reliable and the process of evacuating the sand is very tedious and dusty and these elements are very expensive. The positive effects of this technology would be it helps to mechanize the process of construction and efficiently reduce energy use, emissions and labor. CAD designs allow the designers to design what they want and send it through machinery automatically creating the product that they desire for. This takes place with the help of ‘D-shape printers’ and ‘contour crafting helps in scaling this process up making it useful in the home construction. With the help of this technology, homes can be built safely in lesser time and cost. It offers great architectural flexibility and high level of precision. Advanced technologies can be used in such homes without any additional costs.

How exactly does the machine work?

In order to build your home in a 3D printing archetype, all that you have to do is to make some changes in the architectural design of your home and feed the design to the machine. The machine in turn would build your home layer by layer. It would first deposit a layer of concrete through a nozzle in order to set the foundation. The best part of this machine is that the concrete walls that are built with the help of this machine are more strong that the once that are conventionally built. Besides building the foundation, the machine can do the reinforcement, plumbing, electrical wiring, tiling, painting and also give other finishing touches that are required in a house, which otherwise would’ve required a skilled laborer. As per the estimates made by the experts a house of 2,500 square foot can be custom designed in just 20 hours with the help of this machine. It would be something like waving a wand in air and a house just comes out of thin air! Pure magic!

This concept was brought into the lime light by the collaborative efforts of the European Space Agency and Norman Foster, a London based architect who proposed for a 3D printed moon base built from lunar soil, known as regolith. The structures that were proposed by Norman would be formed around an inflated dome, onto which layers of regolith combined with a binding material would be deposited by a printer that would be controlled by a robot. A specially developed cellular structure to foam would reduce the density of the structure and the amount of binding material required, while producing a shell strong enough to protect its inhabitants from the moon’s inhospitable atmospheric conditions.

Another gargantuan printing is in process in Amsterdam where architects proclaim that are using this technology to build a 13 room traditional Dutch canal house. The building is going to be built layer by layer, the Dus architect are printing out huge honey comb like blocks that fit together like Legos to construct the 3D print canal house. This was done with the help of an on-site printer. We have also the example of A Chinese firm that has gone beyond our imaginations and used 3D printing to build 10 rudimentary prototype houses in 24 hours.

Although 3D printing and home building seems to be an answer to numerous problems but it’s still undiscovered exactly how feasible it is. Many people who belong to this industry feel that the idea seems to be very amazing and innovative, but not realistic. At present the entire process seems to be too time consuming and costly for the average people.

While the future of 3D printing is still quite blurry, such ventures are definitely a boost to the 3D printing industry. Architect Dini sees a potential application in Lunar housing, which is being done by Norman Foster. Another institute called the Massachusetts Institute of Technology (MIT) is actively working towards the development of 4D printing; this is being done by an architect and computer scientist Skylar Tibbits.

Who knows what the future holds for 3D printing in the home building industry and exactly how it will affect the people. Predicting all this is a very difficult task but all that we do know is that the technology and the machine are available that is required making these technological advances. But the actual test of the machine as well as the technology will take place in the hands of time. Only time will test the actual influence of the machine.