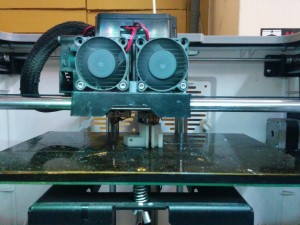

Traditional Extruder in a FlashForge Dreamer 3D printer

In a Traditional Extruder, the extruder motor and the nozzles are both attached (See image above). This kind of extruders are more commonly used. As the name suggests, it is the first type of extruders for3D printers.

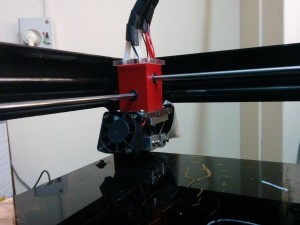

Bowden Extruder in a Mankati Fullscale XT

But as 3D printing technology is developing, 3D printing technologists have come up with another type of extruder – the Bowden Extruder.In this type, the Extruder motor and the nozzle end are not attached (Refer image above). The Extruder motor is called the Cold end, while the nozzle end is called the Hot End. The extruder motor, like in case of a Mankati Fullscale XT 3D printer, is placed at the back of the 3D printer It is detached from the nozzle point. The nozzle point moves with the movement of the rods (in X-Axis and Y-axis). The rods move in both clockwise and anti-clockwise direction, while the nozzle-end starts printing on build plate.

Nozzle-end or hot-end of the Mankati Fullscale XT held by two rods which help it to move in X & Y axis

Extruder motor attached at the back side of the printer, separated from the Nozzle point (unlike the Traditional extruder)

A graphical diagram of the Bowden would be the following:

Because there’s no weight of the Extruder motor above the hot-end, the latter moves faster, as compared to the Traditional Extruder.

Bowden:The Bowden Extruder found its term from the popular Bowden cable. These Bowden cables are found in bicycle wire-cable, Clutch cables, Handbrake cable, Mechanical throttle cables, etc. These cables are specialized to transfer mechanical energy from one point to another.

The Traditional extruders have been the maiden extruders in a 3D printing machine but as time goes we are able to observe innovations like the Bowden Extruders, which aims to make the work faster and less pressure on the nozzle point. Anticipating more developments in the fields of 3D printing, like probably a long-term permanent coating on the build plate for e.g..