The 58th Annual Grammy awards featured stunning performances by Kendrick Lamar, Adele , Taylor Swift and many young contemporary artists. Among all, Lady Gaga stole the show by her incredible homage to David Bowie, deceased, Mighty, and ever leading-edge rock star who died earlier this year. Lady Gaga paid the tribute to David Bowie by singing his all time hits as well as projecting unbelievable visuals and stage effects designed and orchestrated by INTEL tech team.

Among the trailblazing visual effects, digital skin effect with various makeup effects were projected onto Lady Gaga’s face during the performance were absolutely stunning. The major attractions include interactive videos, real time effects, a robotic dancing piano, and interactive holograms . The technology behind the artistic stage visuals involved processes such as 3D scanning, 3D printing, robot programming and Intel’s new Curie technology which sets the stage on fire.

“I like to do things that integrate technology and art with powerful experiences,” said Lady Gaga. “I think that this collaboration with Intel has been very different than anything I have done before. They have really given me so much amazing technology to play with.”

Gaga was inspired by David Bowie’s music wanted to create a memorable performance in homage to him by visually and emotionally immersing the audience with her performance by her impressive digital and engineering feats.

The show started with Lady Gaga’s ‘Space Oddity’, with digital, animated makeup being projected onto her solemn face. The projections had to track the movement of her face as she sang .For that complete splendid effect,Intel’s tech team 3D scanned Gaga’s face in 12 different positions and 3D printed the scans to practice the projections. This prepared the team for the main performance as they were able anticipate for the accurate fit of animations onto Gaga’s face. Infrared sensing cameras were used to track the facial moments.

Asai Nobumichi, who designed the facial projections, explains, “It’s the first time I’ve done it live. Gaga pushed for this technology to be in this show.”

The Intel’s Curie technology also played an important role allowing Lady Gaga to effectively control the visuals and holographic effects as she moved around the stage. The Intel Curie technology was loaded into a wearable ring for the performance, As Gaga moved or danced, the technology captured the moment and send the data to server which would generate the effects in real-time.

Lady Gaga says of the performance, “We wanted to create an expression of not only David Bowie’s magic as a visual artist and musician who combined music, technology, fashion, and art, but also to show that there is magic that can be made with technology that it’s not just big machines and computers and the internet, you can actually create imagery that is other worldly, moments, events, experiences that have never happened before.”

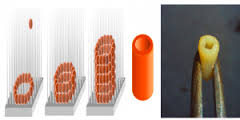

So, here we have the biodegradable 3D printed polymer stent,which eliminates further complications and also serves as drug delivery system

So, here we have the biodegradable 3D printed polymer stent,which eliminates further complications and also serves as drug delivery system