3D printing is in a very early stage in India when compared to various developed economies across Europe, America and Asia. It can be primarily attributed to the cost of printers which are priced upwards $2000 and also to the lack of proper eco-system. But the future holds lot of promise in India with the price of printers falling down and with various new 3D printing applications emerging on a daily basis. According to Zala Shah, Gartner’s research analyst, 3D printing movement started in India in 2012 with various local manufacturers building printers based on the open-source RepRap technology. In the last 2 years, many local printers were produced based on RepRap technology. These printers have certain shortcomings like quality and speed. Many experts believe that it takes another 3-4 years before a truly world-class, low cost desktop 3D printer emerges out of India.

According to a research conducted by 6Wresearch, India’s 3D printing market is projected to grow at around 20 percent CAGR during 2014-19. While various technologies like FDM, SLS, Polyjet, Stereo lithography are in active use in India, Fused deposition modelling (FDM) based 3D printers account for majority of the market in India because of its affordable price and ease of use. Prosthetics, Toys, Gifts are some of the most common applications of 3D printing in India. Many passionate entrepreneurs in India are jumping into the 3D printing bandwagon to bring this technology closer to the common man. These entrepreneurs have already set up some very interesting business models surrounding 3D printing.

Also Indian government started supporting 3D Printing technology in a big way from 2015 onwards. Under Atal Innovation Mission, government is giving mandate to various public schools to set up 3D Printers and teach the kids as part of Atal Tinkering Labs. Also, government is sponsoring INR 10.00 Cr worth rapid protyping related machinery under Atal Incubation Mission. All these policies provide added incentive to entrepreneurs to get into this space.

3D Printing startups in India

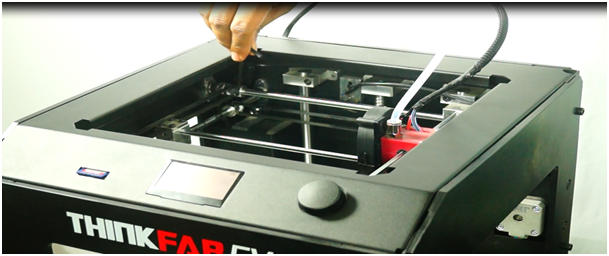

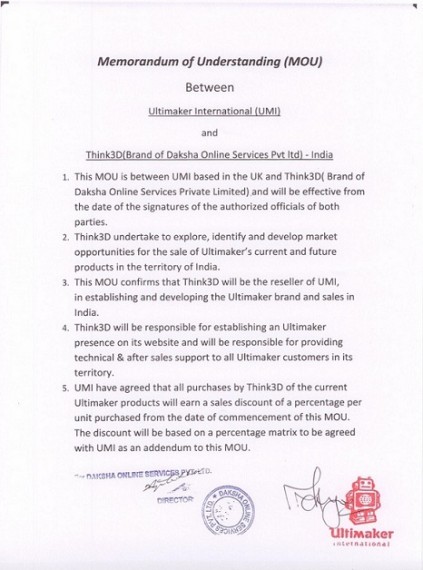

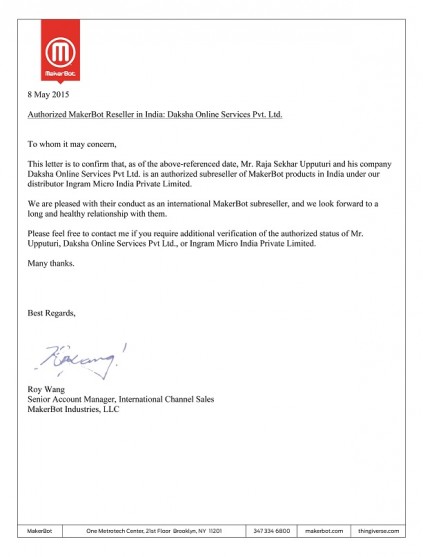

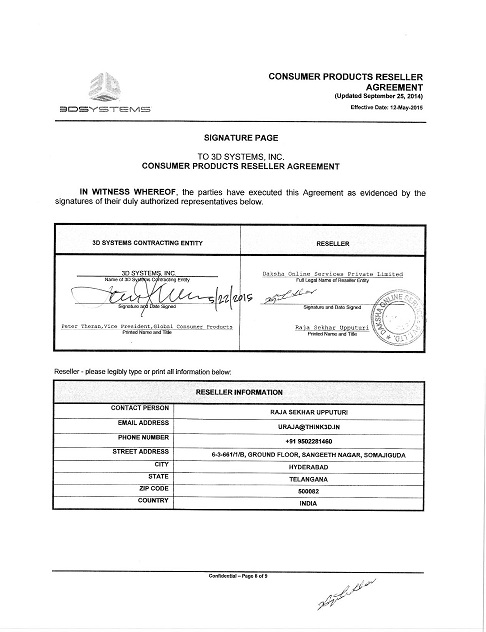

think3D is one such company in India. It was founded by two young passionate entrepreneurs Raja Sekhar Upputuri and Prudhvi Reddy. A small Youtube clip on 3D printing is what it took them to quit their jobs and launch 3D printing company in India. think3D can be considered a one stop shop for all things 3D. As the market is in a nascent stage, they decided to focus on building the ecosystem instead of confining to one particular niche. think3D has a news portal covering all the latest happenings in the 3D printing space, an online store selling various printers and filaments, a dedicated training section to educate people on 3D printing and its advantages.

think3D also launched a seed fund in partnership with iMakr, the seed fund behind world’s largest dedicated retail store for 3D printing. The aim of this fund is to encourage and inspire various 3D printing entrepreneurs in India. Talking about opportunities in 3D printing space Raja Sekhar Upputuri has to say “We strongly believe 3D printing is going to revolutionize the entire manufacturing industry in days to come. It makes manufacturing more local thereby generating local employment. In India, we aren’t finding as much activity or buzz around 3D printing as we see in other parts of the world. It is primarily due to lack of proper awareness and support. So, we launched a seedfund in association with iMakr to build that ecosystem in India. Interested entrepreneurs can apply for any of our programs”.

Another interesting startup in 3D printing space in India is Brahma3, based out of Bangalore. It was co-founded by Nikhil Velpanur and Aravind Nadig in August 2013. This startup focuses mostly on manufacturing 3D printers and on offering 3D print services to the companies. The team built one 3D printer in India with the help of an open-source community . Encouraged by the reception that the product got, Nikhil and Aravind now wants to build a good quality and aesthetically appealing 3D printer from scratch. They both are now focused on building one of the finest quality printers in the world. The Brahma3 team strongly believes that every single industry will be revolutionized by 3D printing technology in ways unimaginable now. Talking about the skill-sets for 3D printing Nikhil says “To work in 3D printing space, one needs to have a multi-disciplinary expertise – The software, the materials, the hardware and so on. Thus the primary requirement for a person to work in 3D printing space is to be open to learning and absorbing as many skills as possible”

ProtoPrint is a social enterprise in 3D printing space in India. ProtoPrint empowers urban waste pickers with the technology to ethically produce fair trade 3D printer filament from the waste plastic they collect. That filament is marked globally providing consumers with a competitively priced, ethically sourced, recycled alternative to virgin plastic. ProtoPrint is a perfect example of how 3D printing technology can be used for social causes. Plastic waste material gets recycled, rag pickers get employment and consumers get the plastic filaments, a key raw material for 3D printing. It is a win-win situation for all the stakeholders.

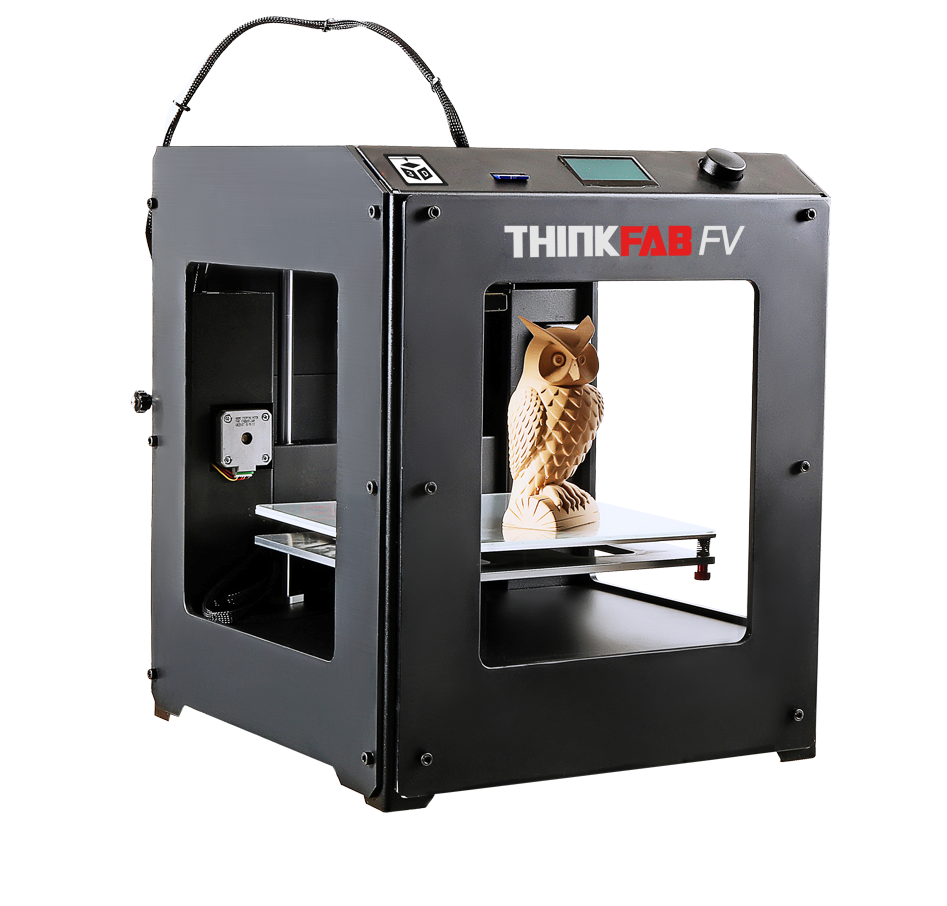

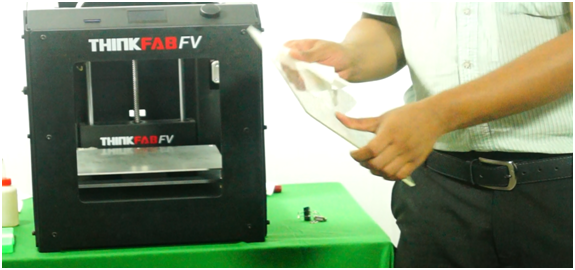

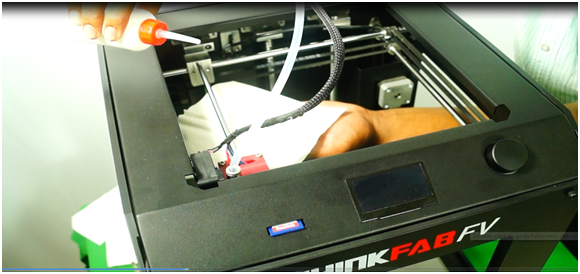

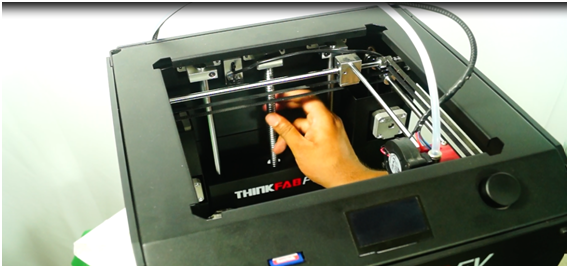

LBD Makers is another start-up co-founded by three young engineers with a mission to create awareness on 3D printing technology for school and college students. When conducting the training sessions, many educational institutions started approaching them asking them for 3D printers for their institutions. They then realized that the 3D printer available in the market had some shortcomings and worked on making a 3D printer that is user friendly.

There are many more such start-ups exploring various business models. And very few of these companies raised investment capital. One such company that raised capital and is noteworthy to mention about is Biotz. Biotz is a Kerala based 3D printing startup offering 3D printing solutions for enterprises. It raised a $50,000 seed fund in April 2013 and has raised Series A round of funding from a group of investors, including a Gurgaon based private equity firm Ncubate. This capital will be used for setting up a manufacturing unit, R&D facility in addition to product development, marketing and hiring.

Challenges in 3D printing industry in India

There are various challenges faced by 3D printing industry in India. But most of these challenges can be attributed to the fact that the industry is still very nascent. And there is no single compelling application built using 3D printing technology. Most of the current applications aren’t really solving the day to day problems. Secondly, not many people are aware of 3D printing. So, the entire market should be educated first on 3D printing industry and on how it can be used to solve various problems in an efficient manner. Also the current range of good quality 3D printers are priced upwards Rs. 1,20,000 ($ 2000). At this price, the printers are very expensive for the majority of the market and the prices should come down by atleast 75% for 3D printing technology to become mainstream.

Except for few investors, majority of the investor community in India plays it safe and invests only in the business models that are copied from successful Silicon Valley business models. Since the 3D printing industry is also in a nascent stage in USA, there is no single highly successfully 3D printing company to emulate. So, investors aren’t backing the 3D printing start-ups in India yet. And this is hurting the eco-system as the hardware is very expensive and thus require lots of investment.

All the 3D printers and raw material required for 3D printing have to be imported from abroad. This adds to the costs making the whole 3D printing process very expensive. Only if materials are locally engineered and produced, the costs of 3D printing will come down. Also the size of 3D printing equipment and the variety of materials that can be used limits 3D printing to only a small set of products and applications.

Summing it all, current 3D printing industry in India faces multitude of challenges and isn’t economically viable. But it is a matter of time before these challenges are addressed to bring the industry into the mainstream.

What investors are looking for?

Many investors in India are maintaining a wait and watch stance when it comes to 3D printing though most of them are aware of 3D printing technology. The reason for that being lack of successful business models in Silicon Valley that can be emulated in India. And this boils down to the fact that industry is in a very nascent stage in India. But with the 3D printing industry evolving at a rapid pace, this is bound to change in the near future. Investors are primarily looking at three aspects when considering to invest in a 3D printing startup.

1. Team – For most investors, having a strong team running the show is absolutely essential. The team should be aware of the complete 3D printing technologies inside out.

2. Value Proposition – 3D printing process impacts the cost, quality and speed of production. So, one important thing investors want to see in the product is its value proposition. If the product can help a company bring down the cost of manufacturing by 50% without any impact on quality, that is a compelling value proposition.

3. End Customer – Startups should have a clear idea on who their end customers and what their requirements are. Only if the founders have clear idea on their end customers, investors will be able to better evaluate them.

Future of 3D printing in India:

3D printing industry has a very bright future as various 3D printing patents are expiring thereby opening up lot of opportunities for Indian entrepreneurs to build more efficient, high quality printers. It is a matter of time before some compelling applications will be built using 3D printing technologies. According to Gartner, consumers and companies spend more than $600 million on 3D printer related products in 2014. Given the rapid advancements in the 3D printing technology, 3D printing will be soon adopted by various industries and consumers alike. Hope that by 2020, many billion dollar 3D printing startups emerge out of India.

Advice to entrepreneurs wishing to get into 3D Printing:

3D Printing is definitely an emerging field and has lot of scope. But unlike mobile technology which has major application in B2C, most of the applications of 3D Printing are in B2B segment and most of these are in Retail, Automotive & Manufacturing industries. Entrepreneurs can choose between manufacturing 3D Printers, trading in 3D Printers, providing 3D Printing services. We advice entrepreneurs to first start with offering 3D Printing services to clients. Identify an industrial zone, set up office there, find few clients and start offering 3D Printing services. It is important to be present in an industrial zone as it provides a catchment area to cater to. If you wish to get more insights into 3D Printing technology, feel free to shoot an e-mail to info@think3d.in