[fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””]

Many people have a misconception that 3D printing is a new technology that is invented in the last few years. This can be attributed to the fact that 3D printing received lots of media coverage in the last few years as the technology entered the consumer space. Otherwise the technology is available in the market for the last 30 years. For major part of its existence, this technology is available at the industrial level and only recently this technology entered the consumer space. In this article, we shall detail the history of 3D printing technology from the time it is invented till date.

[/fusion_text][fusion_title hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” content_align=”left” size=”3″ font_size=”18PX” line_height=”” letter_spacing=”” margin_top=”” margin_bottom=”” margin_top_mobile=”” margin_bottom_mobile=”” text_color=”” style_type=”none” sep_color=””]

Genesis

[/fusion_title][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””]

The earliest 3D printing technologies became available in the late 1980s. Interestingly, various technologies to do additive manufacturing were being explored during that time and most of these technologies came out of the research labs around the same time. In the initial days, these technologies are called Rapid Prototyping (RP) technologies. Technically speaking, Rapid Prototyping / Additive Manufacturing are the most appropriate words for 3D printing. 3D printing is a colloquial word that got into widespread usage as it is easy to understand and as it is a logical extension to 2D printing technology. It is called Rapid Prototyping mainly because it is originally conceived as a fast and more cost-effective method for creating prototypes for product development within the industry.

Charles Hull is considered the father of 3D printing. He filed a patent for a technology that is now known as SLA (Stereolithography Apparatus) and he was issued the same in 1986. So, it is widely accepted that he is the inventor of this technology. Hull went on to co-found the company 3D systems which is one of the largest companies in 3D printing space now. As an interesting side note, the first patent application for rapid prototyping technology was filed by Dr. Kodama in Japan in May 1980. Unfortunately, he didn’t file the full patent specification before the one year deadline after the application. Thus he didn’t receive the patent. Otherwise Mr. Kodama should be considered the father of 3D printing technology.

As mentioned in the above paragraphs, around this time lots of research is going on in additive manufacturing technology leading to diversified methods / technologies to achieve the same end objective (i.e. print the object from scratch). In 1987, Mr. Carl Deckard who was working at the University of Texas, filed a patent in the USA for Selective Laser Sintering (SLS) process. This patent was issued in 1989 and SLS was later licensed to DTM Inc, which was later acquired by 3D Systems. In the same year, Mr. Scott Crump, co-founder of Stratasys Inc filed a patent for Fused Deposition Modeling (FDM) – the proprietary technology that is still held by the company today. Company received patent for the FDM technology in 1992.

At around the same time, lot of research on 3D printing technology was going on in Europe as well. In 1989, Mr. Hans Langer founded EOS GmbH in Germany. The company focused completely on Laser Sintering process. EOS is one of the big companies in 3D printing space now and its products are known globally for their quality and reliability. Various other 3D printing technologies and processes were also emerging during these years like Ballistic Particle Manufacturing (BPM), Laminated Object Manufacturing (LOM), Solid Ground Curing (SGC) and three dimensional printing.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_title hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” content_align=”left” size=”3″ font_size=”18PX” line_height=”” letter_spacing=”” margin_top=”” margin_bottom=”” margin_top_mobile=”” margin_bottom_mobile=”” text_color=”” style_type=”none” sep_color=””]

In 1990s

[/fusion_title][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””]

Nineties saw the proliferation of various companies in the Rapid Prototyping space, all targeted towards industrial use and each with a specific technology. But by end of 90s, only three technologies/companies remained in the market. These include 3D Systems, EOS and Stratasys.

Though most of these technologies are used for Rapid Prototyping (i.e. for creating a sample product before going for mass production), there is lot of research being conducted to build end use items specially for tooling, casting and direct manufacturing applications. This led to the emergence of new terminologies namely Rapid Tooling (RT), Rapid Casting (RC) and Rapid Manufacturing (RM). These terminologies didn’t become very popular in the market and slowly lost their significance. This can be attributed to the fact that the products manufactured through this technology weren’t yet par with those manufactured with traditional manufacturing process. Thus 3D printing / RP technology was still mainly used for rapid prototyping purposes. Though most of these companies / technologies are from the Western Hemisphere, many new companies started emerging in the Eastern Hemisphere. But these companies served only the local needs and couldn’t expand globally.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_title hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” content_align=”left” size=”3″ font_size=”18PX” line_height=”” letter_spacing=”” margin_top=”” margin_bottom=”” margin_top_mobile=”” margin_bottom_mobile=”” text_color=”” style_type=”none” sep_color=””]

In 2000s

[/fusion_title][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””]

By the mid 2000s, the sector started to show signs of distinct diversification with two specific areas of emphasis which are much more clearly defined today. At one end was the industrial 3D printers used to create high value and highly engineered complex parts. These printers are very expensive and the cost of these 3D printers is going northwards. The market for these printers is growing. But the results are only now really starting to become visible in production and applications across aerospace, automotive, medical and jewelry sectors. At the other end were the low cost 3D printers for concept modeling. These printers were used for concept development and functional prototyping. And these were being developed specifically as office and user friendly cost effective systems. However, these systems were all still very much for industrial applications and these printers didn’t enter the consumer realm.

In 2007, 3D Systems launched the first sub $10,000 printer but this printer never became successful for various reasons. Later Desktop Factory announced the launch of sub $5000 printer. Many predicted this to the inflection point for 3D printing industry bringing the printer to a much wider audience. But the company faltered in the run up to production. The company is later acquired by 3D systems in 2008. At around the same time, a new movement was taking shape which changed / advanced the industry leaps and bounds way beyond one’s imagination. It is called RepRap phenomenon / movement. Dr. Bowyer conceived the concept of an open-source, self-replicating 3D printer in 2004 and in the following years, after heavy slog from his team, he was able to build the working prototype of a 3D printer using the deposition process. This event can be considered the precursor of what is now called “Desktop 3D printing”.

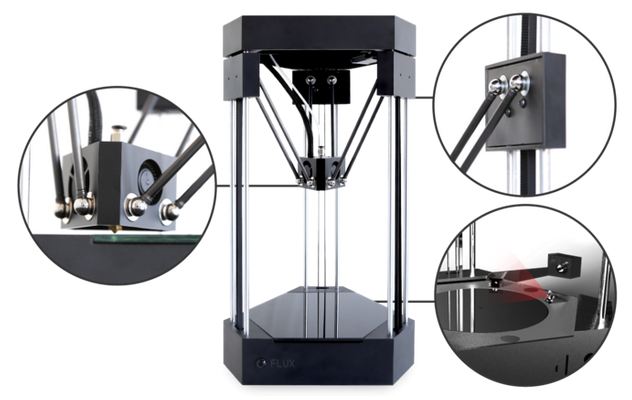

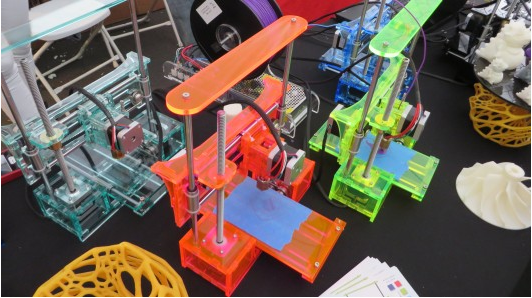

In January 2009, the first commercially available 3D printer based on the RepRap concept was offered for sale. This was the BfB RapMan 3D printer. Makerbot Industries was also actively involved in the RepRap movement and later launched a commercial 3D printer, departing from their open source philosophy. From then on, various 3D printers emerged, each with a marginal unique selling point (USP). Though RepRap was conceived as an open source movement, many took inspiration from this concept and launched their own commercial 3D printers. Unlike in other technologies, various commercial products paved way for open source, in case of 3D printing, it is the open source that paved way for commercial 3D printing and also for desktop 3D printing.

By 2012, FDM became the most popular 3D printing technology for entry level 3D printers and it continued to remain so. As of 2014, many new 3D printers based on FDM technology are launched on a regular basis each with a minor tweaking. Also in 2012, various alternate 3D printing processes were introduced at the entry level of the market. The B9Creator (utilizing DLP technology) came first in June, followed by the Form 1 (utilizing stereolithography) in December. Both were launched via the funding site Kickstarter and both enjoyed huge success.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_title hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” content_align=”left” size=”3″ font_size=”18PX” line_height=”” letter_spacing=”” margin_top=”” margin_bottom=”” margin_top_mobile=”” margin_bottom_mobile=”” text_color=”” style_type=”none” sep_color=””]

Conclusion

[/fusion_title][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””]

As 3D printing technology entered the consumer market in the big way in 2012, various mainstream media picked up on the technology and created huge awareness on this technology in the general public. This led to the extensive hype, way beyond what is possible realistically that 3D printing is currently enjoying. The technology continued to grow in 2013 and is still growing at a blistering pace in 2014.

3D printing is heralded as the next big thing, much bigger than internet as per some experts. Though it can’t be denied that 3D printing is having an impact on manufacturing and industrial sectors, one needs to wait and watch if the 3D printing will affect every sphere of life as proclaimed by many. As it stands now, the technology is still very nascent but is rapidly evolving.

Note: If you wish to purchase 3D printers, you can do so by clicking here. think3D is India’s largest 3D printer store.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]